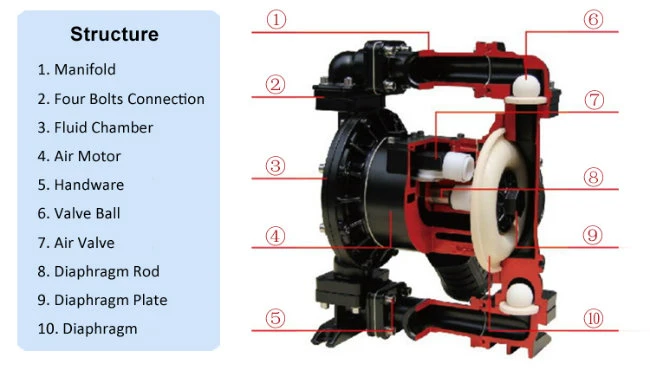

Flocculant Chemical Dosing Double Diaphragm Pump

Package size per unit product 42.00cm * 31.00cm * 64.00cm Gross weight per unit product 26.000kg Flocculant Chemical Dos

Basic Info

| Model NO. | QBK-40 |

| After-sales Service | After-Sales Department |

| Warranty | One Year for The Pump |

| Certification | ISO9001:2000, CE |

| Rated Current | Diaphragm Pump |

| Voltage | Diaphragm Pump |

| Material | Plastic |

| Power | Pneumatic |

| Valve Body Type | Diaphragm |

| Function | Intelligent Type |

| Diaphragm Material | Nitrile Rubber |

| Performance | Corrosion |

| Pump Material | Plastic (or PP, PVDF) |

| Center Block Material | Polypropylene |

| Valve Seat Material | Ss, Teflon, Santoprene, Buna-N, Viton, etc |

| Valve Ball Material | Teflon, Santoprene, Buna-N, Viton, Polyuretane, Et |

| Pump Spare Parts | Diaphragm, Air Valve, Ball, Stainless Steel Shaft |

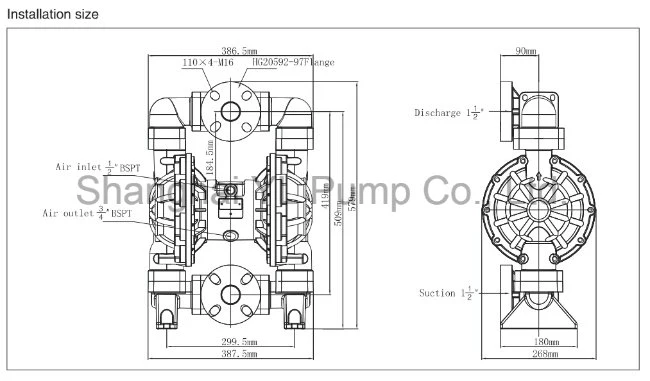

| Connection | Flange Connection or Thread Connection |

| Application | Chemical Industry |

| Features | Explosion-Proof, No Leak |

| Transport Package | Strong Carton or Standard Plywood Case |

| Specification | 40mm |

| Trademark | Y&L |

| Origin | Shanghai, China |

| HS Code | 8414809090 |

| Production Capacity | 1500 Units Per Month |

Packaging & Delivery

Package size per unit product 42.00cm * 31.00cm * 64.00cm Gross weight per unit product 26.000kgProduct Description

Flocculant Chemical Dosing Double Diaphragm PumpIntroduction

QBK series pump is an air operated double diaphragm pump, which is driven by air. It is a kind of positive displacement pumps which volume changes caused by compressing diaphragms in both side. This pump is used for food grade industry.

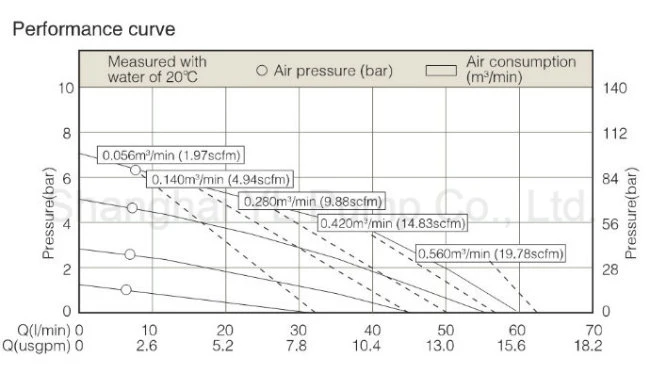

Specification

| Model | QBK-40 | |

| Inlet/outlet Dia. | mm | 40 |

| inch | 1 1/2 | |

| Max. Flow | m3/h | 21.48 |

| L/min | 358 | |

| Head | m | 0-84 |

| Max.Suction stroke | m | 8 |

| Max. Particle Dia. | mm | 5 |

| Max. Air Supply Pressure | kg/cm2 | 8.4 |

| Max. Air Consumption | m3/min | 2.24 |

Features

1. The air diaphragm pump has the function of self priming without rotating parts. It can achieve dry priming and wet priming, which self -priming height is 5m and 8m respectively.2. With sectional type structure, this self -priming pump can be used for conveying two different liquid by double diaphragm.3. Our pump can be used directly as a submersible pump, it uses air as the power source, and does not have the leakage and other security risks. This diaphragm pump has lower cost than submersible pump which is caused by the maintenance of motor.4. Pumps provide stall-free, ice-free operation.5. Bolt joint design provides even sealing pressure for optimal performance.6. Diaphragm,ball and ball seat adopt imported materials with longer service life.7. Due to their pneumatic motor, they could be used in potentially explosive areas.8. Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

Application

1.The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.2. The pump can suck the paint, pigment, glue and adhesive etc.3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.5. The pump can suck various toxin and flammable or volatility liquid etc.6. The pump can suck various wedge water, cement slurry and mortar etc.7. The pump can suck various strong acid, alkali and corrosive liquid etc.8. It can be used as a front-step transmission device of the solid and liquid separation equipment.9. Our pump can be used directly as a submersible pump, it uses air as the power source, and does not have the leakage and other security risks. This diaphragm pump has lower cost than submersible pump which is caused by the maintenance of motor.

Our Service

1. Delivery: Delivery time will be on time as the contract. Usually, the delivery time of diaphragm pump is 5-7 working days.2. Warranty: 1 year for the pump body, 3months for the main working parts.3. Package: According to your quantity, we use strong carton or plywood case which is durable for ocean transport.4. Shipping: By Sea, By Air and By International Express.5. Payment: we can accept T/T, L/C , West Union and so on.6. Pre-sales Service: According to your requirement, we will give you our profession advice of pump solution.7. On-sales Service: We will clearly show you everything in fact when you place an order with us. We will takes photos or videos to show you our production situation.8. After-sales Service: We will full report you the production progress and plan. Meanwhile, we will follow up the pump working conditions per three months when the pumps put into use, and can send the spare parts to you within one week if u need.

Our Company

Send to us